PRODUCTS / SERVICES & SOLUTIONS

High Temp Electronics

Electronics Built to Withstand Extreme Heat – Proven to 225 °C

From oil & gas wells to avionics and space, Spectrum Control designs and manufactures high-reliability electronic solutions that thrive where standard PCBs fail.

- Thick-film ceramic interconnects rated to 225 °C

- Hermetic packaging to block moisture & chemical ingress

- Proven reliability models: physics-of-failure + accelerated life testing

- MIL-PRF-38534 Class K and ISO-17025 certified

The Spectrum Control Advantage

With over 70 years of experience in high-reliability electronics, Spectrum Control offers end-to-end capability that spans design, assembly, testing, and qualification. Our solutions are trusted across aerospace, defense, energy, and space industries, where mission assurance is non-negotiable. By combining proven heritage with advanced methods, such as physics-of-failure modeling, Bayesian accelerated life testing, and digital twin integration, we deliver electronics that are not only reliable today but future-ready for decades of service.

| Operating Temp Range | −55 °C to +225 °C continuous |

| Substrates | Thick-film ceramic, hermetic ceramic |

| Devices Supported | SOI, SiC, GaN, GaAs dies; SMT on ceramic |

| Packaging | Chip & wire, monometallic bonding, hermetic sealing |

| Testing | Thermal cycling, vibration, shock, high-pressure testing |

Why Traditional Electronics Fail in Harsh Environments

Design for Reliability

Our solutions are designed with failure modes in mind:

-

Thermal stress & fatigue: Substrate expansion, die attach, wire bond fatigue addressed via materials matched to thermal coefficients.

-

Packaging & sealing: Hermetic sealing to mitigate moisture, pressure, and chemical ingress.

-

Electrical stability: Ensuring low thermal drift for critical performance metrics (e.g. amplifier gain, sensor accuracy, timing).

-

Mechanical robustness: High vibration & shock qualification to space / energy industry standards.

Operating temperatures

- Standard temperature -55°C to 150°C

- High Temperature 150°C to 175°C

- Extreme high temperature 175°C to 200°C

- Ultra high temperature 200°C to 225+°C

Applications

Oil and Gas Production

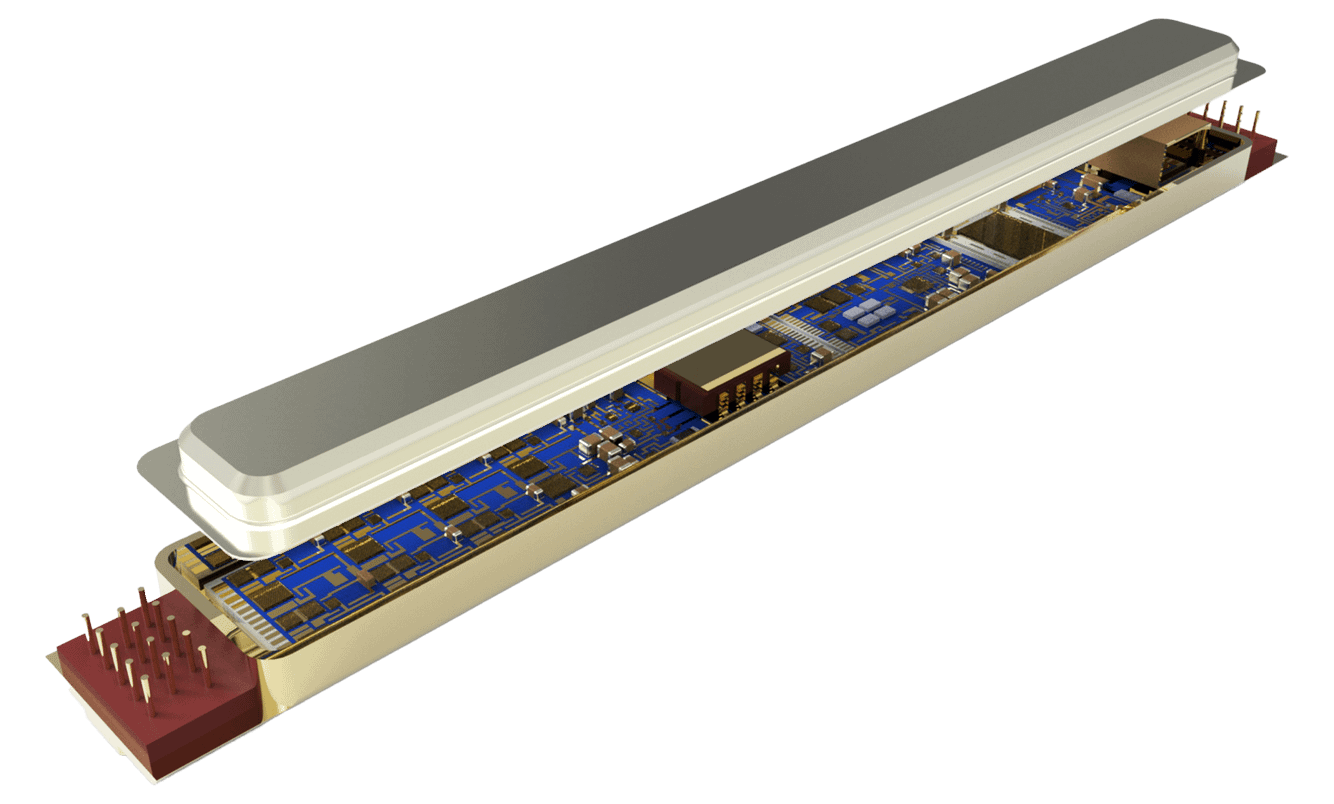

Spectrum Control has a strong heritage of providing high temperature electronics to the oil and gas industry. Our specialized techniques of bare semiconductor die on thick film ceramic interconnect overcome the high temperature performance and reliability limitations of traditional glass fiber laminate printed circuit boards.

Spectrum Control's high temperature technology can reduce costs and downtime by prolonging the life of expensive drilling and monitoring equipment, with features including extended lifetime at 225°C and on-going development in ultra high temperature ranges of 200+°C. We provide custom microelectronic solutions to reduce unnecessary and costly downtime due to the failure of short lifetime electronics within equipment encountering extremes. This includes Measurement While Drilling (MWD), Logging While Drilling (LWD) and wireline in intelligent completions equipment. Our product solutions are specifically designed to fit down to 1" tubes to provide an ideal solution for small diameter tools operating at depth.

- Measurement While Drilling (MWD) and Logging While Drilling (LWD)

- Intelligent Well Completions (IWC)

- Wireline electronics

- Geothermal

- Solid state anemometer electronics

- Offshore safety control systems

- Pressure control sensors

- Motor controllers

Medical Systems and Healthcare

Spectrum Control manufactures custom high-temperature electronic components for the medical and healthcare industries to ensure that the reliability and electronic performance of surgical tools and instrumentation are maintained. Here are some of the many applications that benefit from high-temperature solutions.

- Autoclaves

- Surgical drill motor controller products

- Blood electrolyte sensors

- Blood analyzer control hybrid assemblies

Avionics

Spectrum Control offers a wide range of custom design and manufacturing solutions for aircraft electronics. From fuel pump control assemblies to highly integrated multi-layer hybrid microcircuits. Here are some examples:

- Aircraft altimeters

- Heads up displays

- Digital engine controls

- Power supplies

Space

Our custom products have been produced for a wide variety of satellite requirements include low-cost cost radiation-hardened, high-reliability die packaging. Our MIL-PRF-38534 Class K qualification enables us to support quality requirements of both military and commercial space programs.

Areas of specialization include contract manufacture of hybrid microcircuits, and custom thick-film hybrid electronic modules, as well as our in-house, independently managed ISO 17025 accredited test facility.

Talk to us about your high temp application

Use this form to start the conversation or to request more detailed information about our custom high temp/high reliability hybrid MCM solutions. One of our team members will be in touch.