What Is An EMI Filter And How Does It Work?

EMI filter designs protect sensitive equipment from being damaged by high levels of electrical noise. Almost all electronics contain an EMI filter. It may be embedded into a printed circuit board or used as a separate, standalone device. This includes electronics being used in mission critical, military/defense, secure communications, industrial, medical, and energy platforms.

EMI filters function by absorbing the energy that interferes with other electronics in proximity. There are standards in most countries limiting the amount of noise that can emanate from a source. All electronics must follow these regulations in their design.

What Is EMI?

Electromagnetic interference (EMI) occurs when two or more electrical circuits interfere with each other. This type of disturbance can cause radio frequency (RF) noise, which may disrupt functionality and communication between devices.

EMI can be from intentional or unintentional sources, continuous or intermittent, and at a single frequency or across a broad range of frequencies. EMI encompasses the entire electromagnetic spectrum but is most applicable to modern electronic devices over the frequency range of 10 kHz to 10 GHz.

Key Concepts

-

Insertion Loss: reduction of signal power (noise) resulting from the insertion of a device into a circuit (expressed in dB)

-

Energy Coupling: transfer of electrical energy from one circuit segment to another

-

Energy Storage: capture of energy from a source at one moment in time to be used at a later moment in time

-

Signal Conditioning & Electromagnetic Spectrum Management: EMI protection products manage the signal and energy that exist in 50Hz to 10GHz range of the electromagnetic spectrum

Why Do We Need To Have EMI Filters?

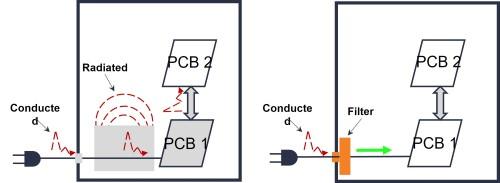

EMI filter designs provide energy efficiency, and power management, addressing both conducted and radiated EMI for aircraft, rugged and unmanned vehicles, power supplies, automation equipment, and diagnostic imaging. And yes, there are also EMI filters in that smartphone in your pocket and the smartwatch on your wrist.

EMI filtering components and assemblies also provide solutions for Electromagnetic Compatibility (EMC). EMC are the laws and regulations of the country where the products are being distributed. All electronic and electromechanical products must conform to EMC compliance.

Engineers should always seek to reduce the levels of interference in their electronic products during the design phase. Often, it’s during the EMC testing phase when the amount of EMI is discovered.

What Are The Different Types Of EMI Filters?

There are many EMI filters available. They come in two major categories–active and passive.

Active filters use an internal power supply to generate electricity. Active EMI filters work by detecting the voltage at the input and generating a current flow in the opposite direction. This effectively removes the EMI current causing a disturbance. This technique makes use of the active electronic elements and applies an internal circuit to block out unwanted frequencies. By looking at EMI filter requirements, design engineers will achieve a reduction in size, cost, and improved performance.

Passive filters absorb unwanted energy. Passive EMI filters reduce emissions of a power electronic circuit and are constructed from only passive components: capacitors, resistors, transformers, and inductors. These elements are fine tuned to produce electrical resonance at a single frequency, or through a band of frequencies. Passive EMI filters will suppress harmonic currents and decrease voltage distortion in sensitive elements of electronic systems.

Which Type Of EMI Filter Is Best For My Design?

There are several benefits to using a passive EMI filter over an active EMI filter, including the strength of its internal elements. They are better for large signals common in modern electronics, are often more economical, and power supplies are unnecessary.

Best EMI Filter Requires Correct Installation

-

Filters are only the first step in meeting radiated emissions requirements

-

Filters should be mounted at point of entry

-

Filters require low impedance ground contact

-

Filter input and output lines should be shielded from each other

-

System level openings and ground points follow Lambda/20 rule

EMI filters protect sensitive electronics from damage caused by high levels of radiation emitted by other electronic equipment. They extract unwanted current conducted through wiring or cables that can interfere with signal and power lines, while allowing desirable currents to flow without restriction.

There are a wide variety of EMI filters available in today's market to fit any requirement or design structure. This includes panel mount filters with resin or glass seals, surface mount filters with minimal PCB footprint, board mount EMI filters, d-subminiature or circular connectors for managing EMI at the signal and power I/O, and single phase and 3 phase power line filters for the AC or DC power entering the system.

EMI filters can be built for weight saving applications or for AC and lighting withstand in transient environments. There are many standard high-quality part numbers on the US government's qualified product list (QPL) built to meet or exceed various standards and designed for rugged and RoHS environments.