Filtered Circular Connectors Overview

What is a EMI Filtered Circular Connector?

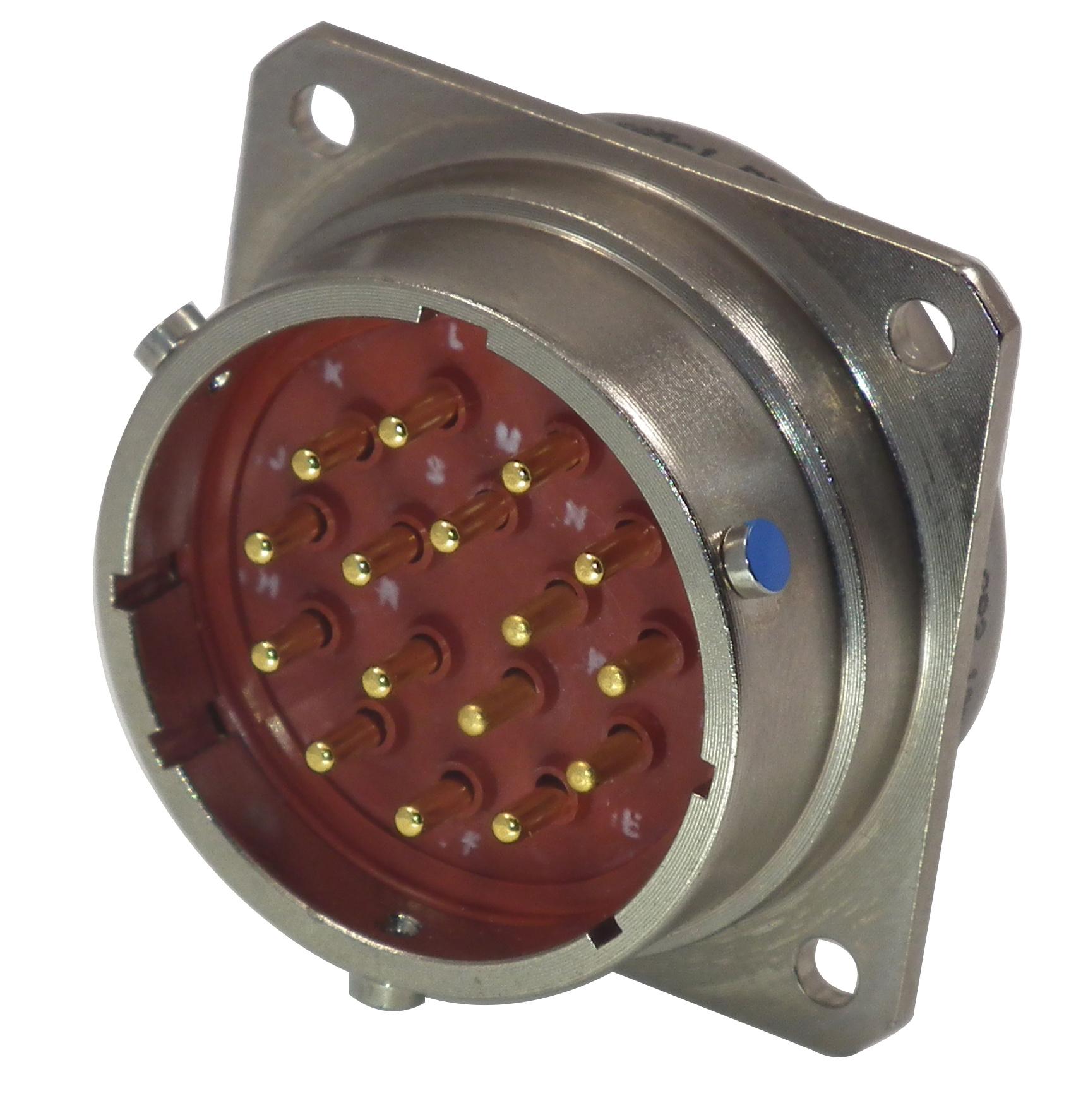

Circular connectors offer the capability to transmit power and electrical signals in multi-pin designs. They are easily installed and removed. Because of their cylindrical structure, they are sealed to provide the toughest performance in the harshest of applications. They have outstanding mechanical sturdiness and a higher strength-to-weight performance critical for high shock and vibration environments. EMI Filter Circular Connectors strip unwanted electromagnetic interference (EMI) or transient voltages from signal lines by incorporating ceramic capacitors. This type of connector provides effective EMI filtering, reducing the amount of real estate required within a product enclosure.

Vertical Integration

As a fully vertically integrated company, Spectrum Control is truly unique among connector suppliers. Spectrum Control’s filtered EMI connector offerings are fully vertically integrated and manufactured in the USA. Components including ceramic capacitors and shells are manufactured by our State College, PA facility, providing our customers with high-quality parts with the industry’s shortest lead times.

At Spectrum Control, we know it is rare to find an of-the-shelf connector that completely satisfies the environmental, mechanical, and electrical requirements of demanding, high reliability applications. Our engineering team is ready to modify one of these existing designs or start with a “clean sheet” to ensure our connector satisfies all of your requirements.

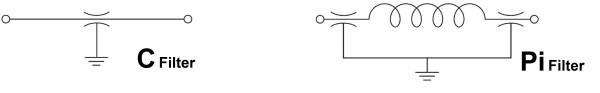

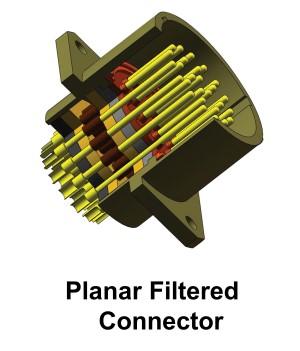

This premium line of custom circular EMI filtered connectors are completely intermateable with MIL-DTL-38999 Series III. Spectrum Control also offers custom circular connectors in an EMI filtered style, including MIL-DTL-55116, -83723, -24308, -26482, and -5015. Our filtered compact shell connectors provide an effective filtering device that reduces the amount of real estate required within a product enclosure. Using our expertise in EMI filter design and manufacturing, we offer planar-style filtered arrays available in C and Pi circuits. Other filter circuits, including transient protection, are available.

In addition, we can accommodate your quick-turn schedule for prototyping by adding planar capacitor filtering to the rear of a standard connector.

Filtered Circular Connector Part Configurator

Custom EMI Filtered Circular Connectors Product Request Form

EMI Filtering a Circular Connector

Types of Filtered Circular Connectors

Composite Shell

For even greater design flexibility, Spectrum Control offers composite shell circular connectors. These composite connectors feature shells fabricated from high grade thermoplastic and designed to replace traditional metal connector shells for substantial weight reduction. The composite shell maintains the form, fit and function of the original connector shell, making it ideal for applications where weight is a critical factor. A composite shell version of any Spectrum Control’s circular connector designs is available.

Custom Mechanical Packages

Our vertical integration includes a unique material process and extensive machining capabilities, allowing us to easily modify the mechanical package of any connector, ensuring fast and affordable custom designs. Other connector manufacturers mold their composite shells, making custom designs expensive. At Spectrum Control, custom mechanical variations are machined allowing for unique packages without traditional tooling charges.

- Stainless steel, aluminum, composite shell for harsh environmental and weight-sensitive application

- Cadmium, nickel, black nickel-zinc plating for military and RoHS environments

- AC and lightning withstand designs for transient environments (up to DO 160 Level IV)

Hermetically Sealed Connectors

Spectrum Control also has a family of hermetically sealed circular connectors that protect against changes in atmospheric pressure and exposure to humidity, grime, and chemicals, making them ideal for aerospace engine control, hydraulic, and caustic environments where harsh conditions could exist. The hermetically sealed connector’s receptacle has a seal of 10-7cm3 and comes in filtered and unfiltered versions.

Electrical Specifications

- Operating Temperature: -55°C - 125°C

- Capacitance: up to 200nF in most configurations, see table below

- Capacitance Tolerance: ±25%, +100%

- Voltage Rating: 200VDC

- Dielectric Withstanding Voltage: 500VDC

- Dissipation Factor: < 3.5%

- Insulation Resistance: 1000 MΩ, μF or 10KMΩ

Insertion Loss

Circular EMI Filtered Connector Capacitance Table

| Capacitance Code | Capacitance Value | Circuit Availability |

| 251 | 250 pF | C |

| 501 | 500 pF | C, Pi |

| 120 | 1000 pF | Pi |

| 122 | 1250 pF | C |

| 252 | 2500 pF | C, Pi |

| 502 | 5000 pF | C, Pi |

| 103 | 10,000 pF | C, Pi |

| 203 | 20,000 pF | Pi |

| 253 | 25,000 pF | C |

| 503 | 50,000 pF | Pi |

Connector Styles

Wall Mount Filtered Circular Connector

Jam Nut Filtered Circular Connector

Termination View

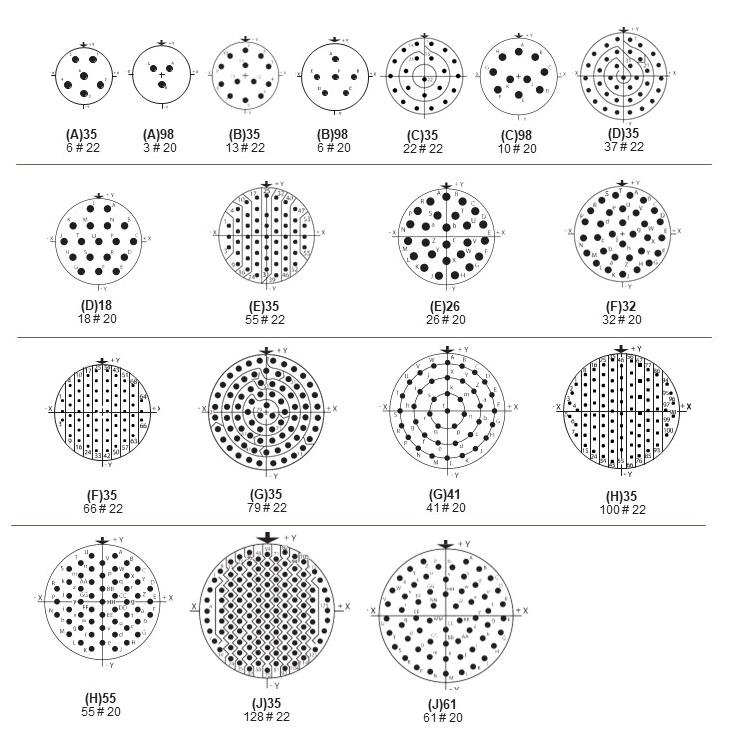

Insert Configurations

About Spectrum Control

Spectrum Control has been a leader in providing application specific EMI filtered connector solutions since its founding in 1968. Our brand offers the industry’s most extensive line of circular connectors that are designed for high reliability or demanding environmental applications such as commercial aviation and avionics, of highway and agricultural vehicles, high reliability power supplies, as well as all airborne, ship or ground-based military applications.

At Spectrum Control, we know it is rare to find an of-the-shelf connector that completely satisfies the environmental, mechanical, and electrical requirements of demanding, high reliability applications. Our engineering team is ready to modify one of these existing designs or start with a “clean sheet” to ensure our connector satisfies all of your requirements.