EMI/EMC Filter Basics

Introduction

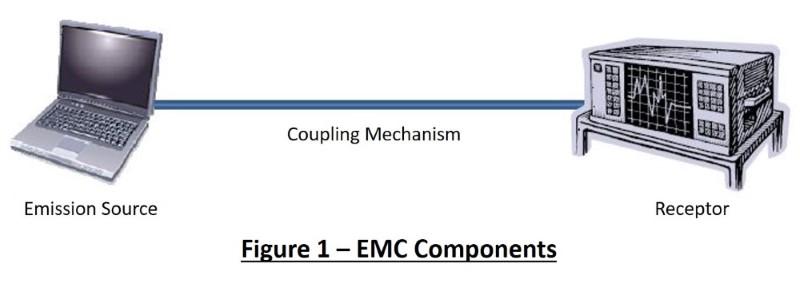

Electromagnetic Compatibility (EMC) ensures that multiple electronic devices can function acceptably within the same electromagnetic environment but not interfere with each other's operation. Here we will discuss the basics of EMC standards, test methods, and using mitigation techniques.

Sources of EMI

Electromagnetic Interference (EMI) is an electromagnetic emission that causes interference in another electronic device. EMI can be from intentional or unintentional sources, continuous or intermittent, and at a single frequency or across a broad range of frequencies. EMI encompasses the entire electromagnetic spectrum but is most applicable to modern electronic devices over the frequency range of 10 kHz to 10 GHz.

Unintentional EMI sources include switch-mode power supplies (SMPS), digital devices, brushed DC motors, high-voltage ignition systems, and fluorescent lighting. SMPS is the most common unintentional EMI source; since they are now used almost exclusively in LED light bulbs, digital devices, and battery chargers for cell phones and laptops.

Intentional EMI sources are most commonly radio frequency transmitters, whose emissions are often referred to as Radio Frequency Interference (RFI). This includes AM radio, FM radio, television, cell phones, Wi-Fi, Bluetooth, and many other fixed and mobile radio communication systems used by aviation, emergency services, police, and the military.

Intermittent EMI includes transients that can cause catastrophic damage to electronics, including electrostatic discharge, lightning, inductive kickback, and electromagnetic pulse events (EMP).

EMI Coupling

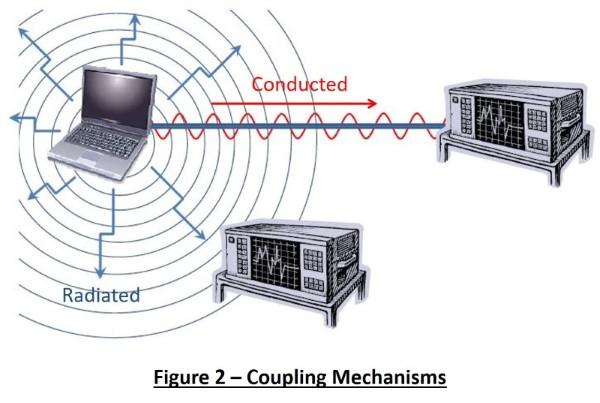

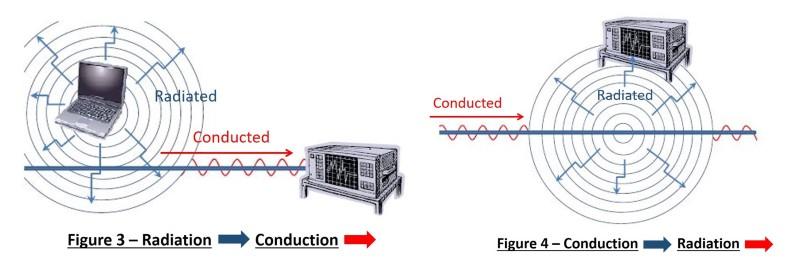

EMI coupling from the source to the receptor can be conducted through wires, radiated through the air, or both. Radiated emissions readily penetrate non-conductive materials such as air, space, plastic, wood, and insulators. Radiated emissions become more challenging to mitigate at higher frequencies because higher frequencies have shorter wavelengths that are more effectively radiated by typical wire lengths.

Real-world EMI situations are often a combination of both conducted and radiated emissions, with any or all wires and cables acting as receiving or transmitting antennas.

EMI Suppression

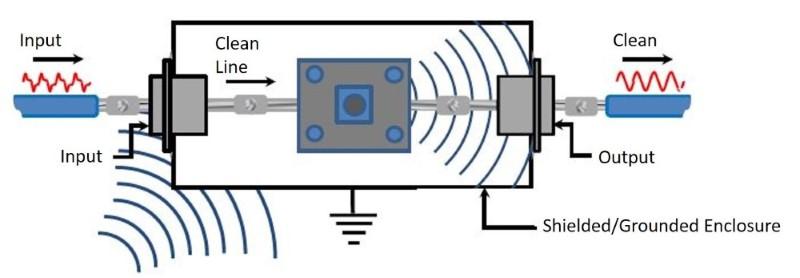

EMC requires proper grounding, filtering, and shielding, i.e., you can’t simply increase filtering to make up for a bad ground or ineffective shielding.

Radiated EMI often requires shielding electronic components inside a metallic enclosure, and maintaining that shield requires cables and wires to be filtered at the point of entry. Filters reduce conducted EMI on wires and cables into and out of the enclosure. Point of entry feedthrough filters requires low-impedance coaxial connections to the metal enclosure to function correctly.

Basic EMI Compliant System

Compliance Testing

The two types of EMC testing are emissions and immunity. Emission testing verifies the frequency and amplitude of a device’s emissions are below standardized limits. Immunity testing confirms the acceptable functionality of a device when exposed to standardized EMI levels.

Emissions are measured using a Line Impedance Stabilization Network (LISN), current probe, or antenna connected to an EMI receiver that scans the desired frequency range. Emissions under the limit are passing, and emissions over the limit are failing.

Emissions Testing

Radiated Emissions Test Setup

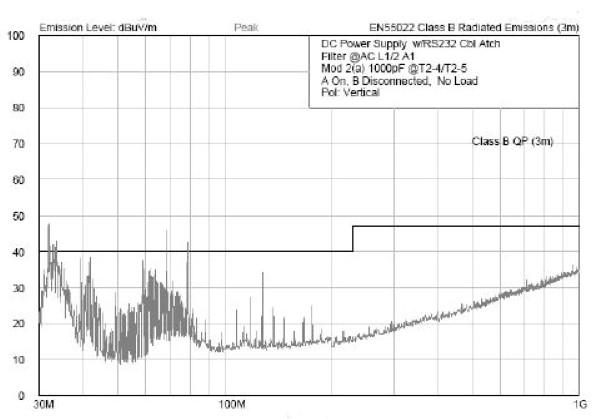

Radiated Emissions Test Data

Conducted Emissions Test Setup

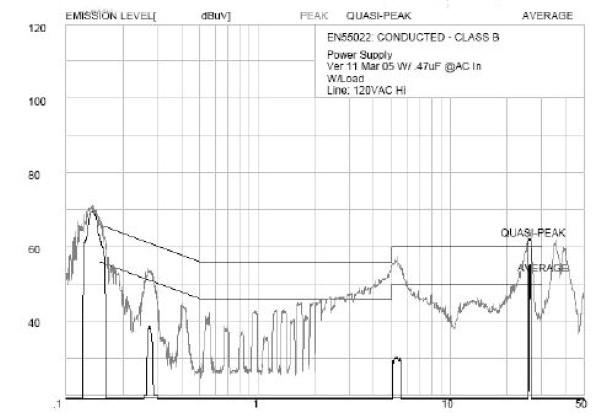

Conducted Emissions Test Data

Immunity

Immunity is performed by injecting EMI through a Coupling/Decoupling Network (CDN), current probe, or antenna and verifying the device's functionality under test. The pass and fail indications are not seen on the EMC test equipment but are determined by monitoring the functionality of the device being tested while it is exposed to EMI.

Emission and immunity testing is broken down into the four basic EMC tests 1) Conducted Emissions, 2) Radiated Emissions, 3) Conducted Immunity, and 4) Radiated Immunity. Conducted emissions and conducted immunity testing will not use an antenna, whereas radiated emissions and radiated immunity testing use antennas. If there is an antenna in the setup, radiated emissions or radiated immunity tests are performed.

Immunity Testing

Radiated Immunity Testing Set-Up

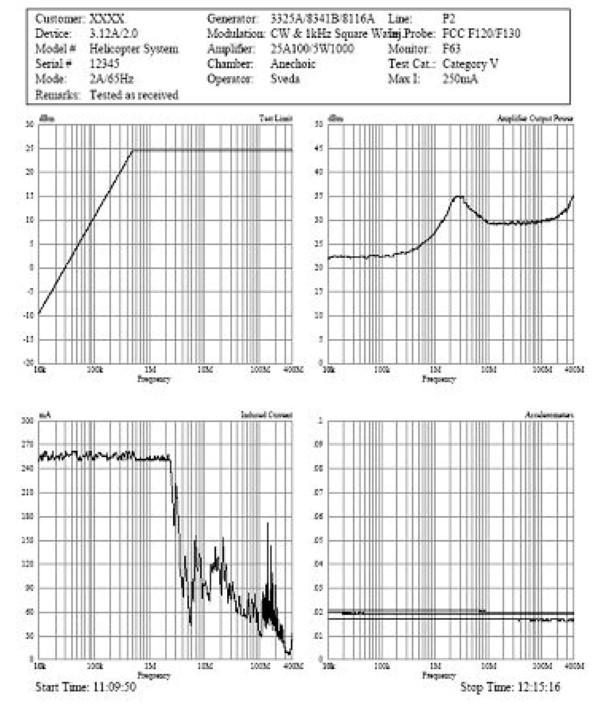

Radiated Immunity Testing Data

Conducted Immunity Testing Set-Up

Conducted Immunity Testing Data

Real-World Considerations

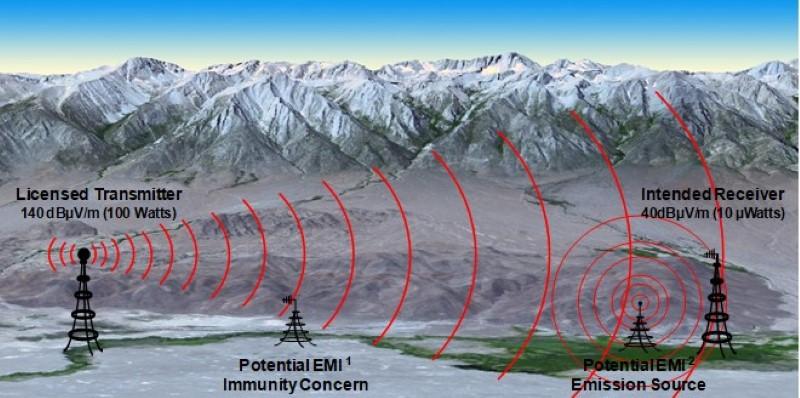

The typical difference between EMI emission limits and immunity test levels is 100,000 to 1 or 100 dB. Is this a 100 dB safety margin? If electronic devices in a given environment are limited to such low emissions levels, why are these devices required to handle such high levels of immunity? The reason is that electronic devices must operate in close proximity to both radio transmitters and radio receivers. Radio transmitters generate high-level RFI to communicate over great distances. Radio receivers are very sensitive in order to detect these signals. Immunity test levels simulate the energy levels that electronic devices will be exposed to when they are operated nearby radio transmitters. Emission limits ensure that a device’s EMI emissions will not interfere with the reception of nearby radio receivers.

Notes

-

Equipment expected to operate in close proximity to radio transmitters must be immune to EMI levels in excess of 10 V or 140 dBμV.

-

Equipment expected to operate in close proximity to radio receivers typically limits EMI emission levels to less than 0.0001 V or 40 dBμV.

Standards and Specifications

From a global perspective, most governments have rules and regulations related to the control of EMI and call out specific standards for testing devices to ensure EMC compliance.

In the U.S., the Federal Communications Commission (FCC) handles EMC guidelines for commercial equipment. The Code of Federal Regulations (CFR) section 47 Parts 15, 18, and 68 contain relevant information that all engineers should be aware of when designing class A and B devices.

The US Military has its own standards, which are significantly more stringent. These guidelines are detailed in a wide range of military standards, such as MIL-STD-461 and MIL-STD-464.

The International Electrotechnical Commission (IEC), via its International Special Committee on Radio Interference (CISPR), creates globally accepted EMC standards.

Test capability at Spectrum Control is extensive and covers a large number of requirements related to the FCC, US Military, and the IEC. Some test capabilities are listed below, but this list continues to evolve and expand to support market expectations.

Military

-

MIL-STD-461 A/B/C/D/E/F/G

-

MIL-STD-1399 Surge

-

MIL-STD-704

-

MIL-STD-1275

Industrial

-

FCC Part 15 Emissions

-

CISPR 11, 14, 22 Emissions

-

CISPR 25 Emissions

-

IEC 1000 x 4 Immunity

Medical

-

EN 55011

-

EN55022

Conclusion

Electromagnetic Compatibility has become an essential aspect of electronic equipment and systems design. Equipment manufacturers must stay up to date with continually evolving EMC legislation. It is important to understand EMC since equipment failures at the compliance level can delay product deliveries and increase development costs. EMC failures at the user level can mean returned equipment, loss of future business, and potential hazards in critical applications.

Spectrum Control's diagnostic testing capabilities and world-class manufacturing provide EMI filter solutions to satisfy global EMC standards while meeting unique design parameters.